Technologies Development and Implementation

A moment comes for each enterprise when it thinks about expansion. An enterprise can expand its existing production, or it can introduce new innovative products with higher added value. SIA KATAP offers glass processing companies to develop and introduce various glass lamination technologies in accordance with the customer’s wishes and intended target markets. Glass lamination, safe glass production makes it possible to produce products with significant added value.

Steps

- Study of existing production and specification of goals

- Design of the production process and line

- Identification and selection of production equipment and materials. Budgeting

- Purchase and installation of means of production

- Staff training and technology implementation

Enquiry

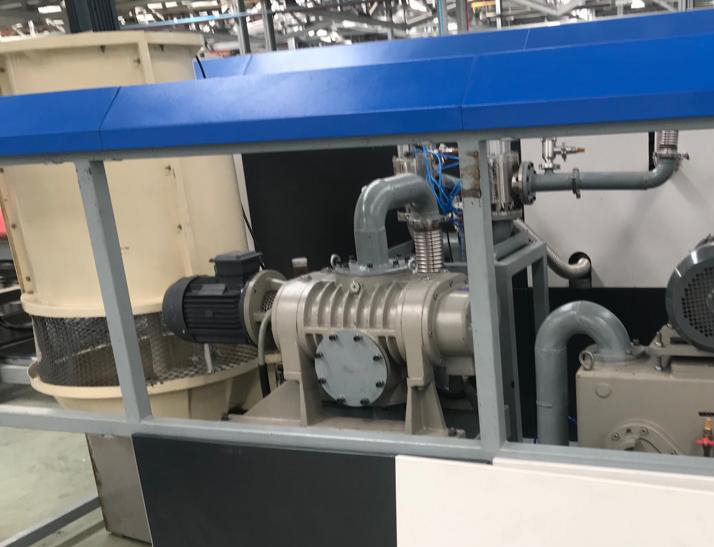

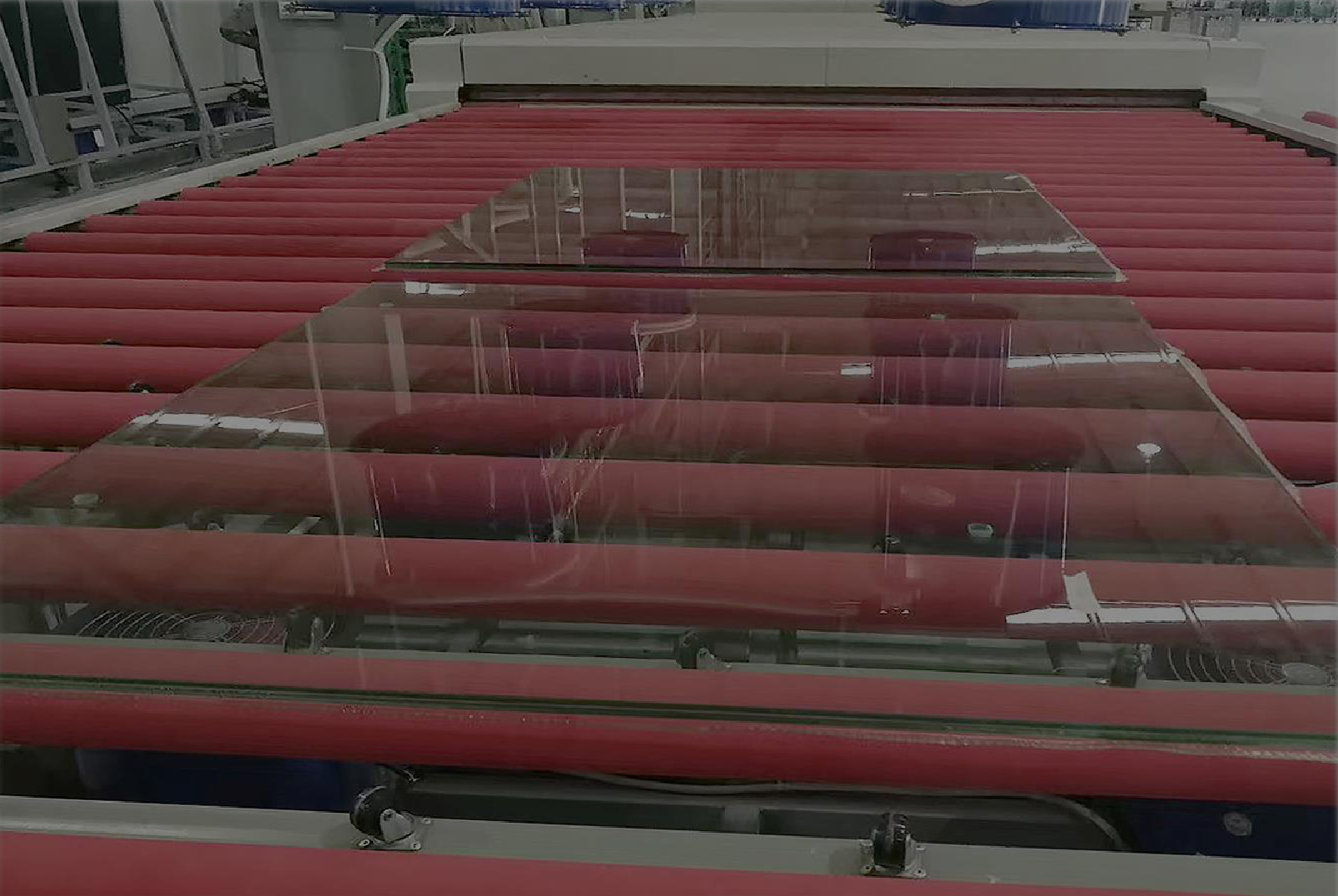

Glass lamination – triplex production

- The general term “lamination” means the production of multi-layer glass structures using polyvinyl (PVB) or ethylene vinyl (EVA) film or a special liquid-like material – resin, and structures made in such way are called laminated glass or triplex.

- Laminated glass can consist of several layers of the same or different glass, which can be straight or curved in accordance with the given shape. The thickness of the obtained laminated glass depends on the number of glasses and their thickness, as well as the thickness of the lamination layers.

- The most common type of laminated glass used in constructions of windows of different safety classes and windscreens is the so-called triplex – a structure made of two glasses and an intermediate laminated layer. In some cases, a film can be glued onto the glass – the so-called single-sided lamination.

- The main advantage of laminated multi-layer glass structures is its safety in case of destruction. Since fragments during destruction remain “hanging” on the elastic film during destruction, there is no danger that glass fragments can cause injuries. Using lamination, it is possible to produce structures that can serve both as a protective glass against damage and blast waves and as a bulletproof, shockproof and fireproof glass. Laminated glass also protects well against UV radiation. It should be noted that lamination (in contrast to tempering) does not increase mechanical stability.

- Glass lamination is also used to produce various visual and/or functional effects. For example, the “smart glass” function has been popular lately, when glass changes its state from transparent to non-transparent by cutting the current supply, or lamination of LED matrices between the glasses.